IMSG PROCEDURE for IHM control and maintenance

Introduction

This procedure is based on the requirements of Res. MEPC 222 (64), 223 (64) and describes the process of collecting, processing, analyzing and accumulating information on the presence of hazardous substances in equipment or materials supplied on board the vessel, according to the classification of Res. MEPC. No.269 (68).

Definitions

Hazardous materials - materials containing substances of Table A and Table B (Res. MEPC 269 (68)). These substances include:

According to this Procedure, hazardous materials do not include liquid substances (oil products, waste water, bilge water, ballast water).

Declaration of materials - a document confirming that there are no hazardous substances in the materials supplied to the ship.

Shipping company - a company that provides technical management of the ship and is responsible for all supplies on board the ship of equipment and materials.

IHM company is a company that verified all materials supplied on board a vessel for the presence of hazardous substances. An IHM company must be flag accredited in the field of hazardous substances assessment.

Reporting period - 12-month period during which the supplied materials are monitored. At the end of the reporting period, the company is provided with an annual report, including the results of control for the entire period, as well as all acts / declarations on the inspection of hazardous materials.

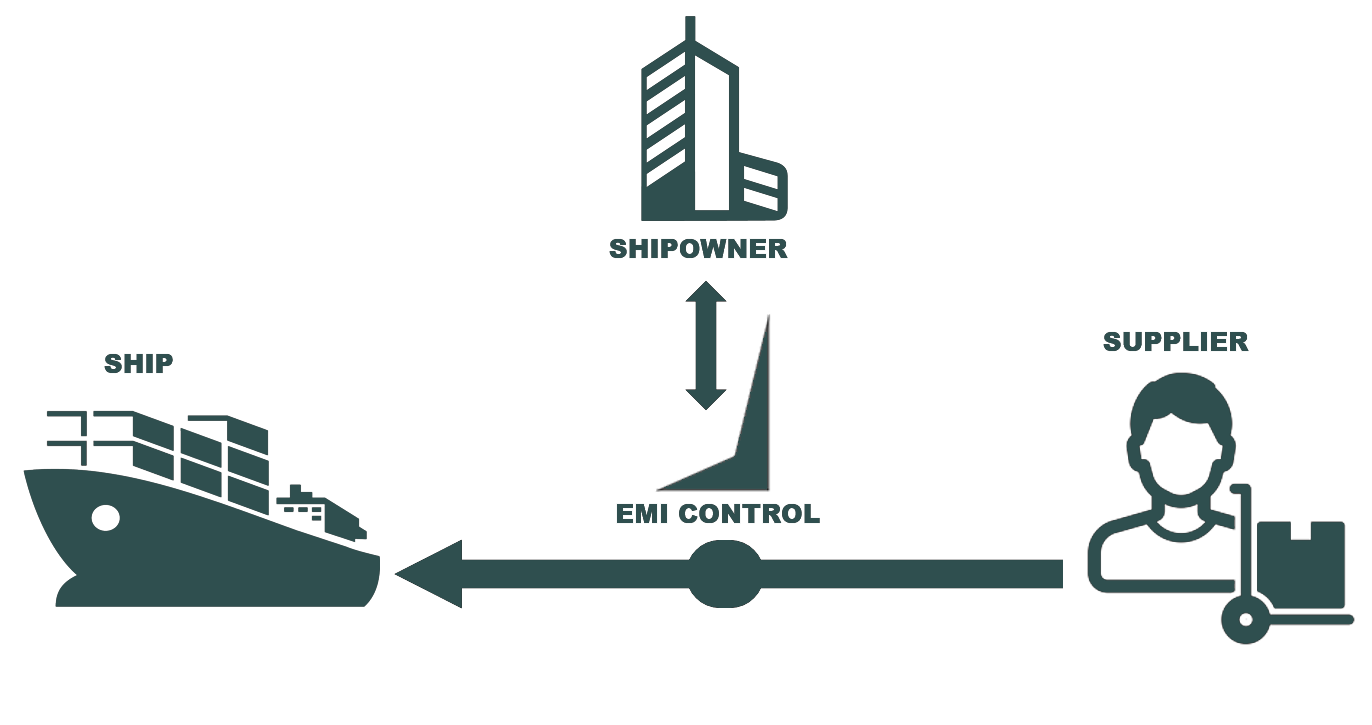

Interaction

According to the contractual relationship, the shipping company provide to the IHM company the process of assessing the presence of hazardous substances in the materials supplied to the ship.

IHM company:

The control over the interaction of the two companies is carried out by an Official (DPA). Maintenance and control of materials supplied on board the vessel is carried out on a regular basis during the reporting period.

Material assessment procedure:

According to the requirements of the Hong Kong Convention - any material supplied on board the vessel must be assessed for the presence of hazardous substances in it. The assessment is carried out according to the manufacturer's documents or, in the absence of the manufacturer, according to the results of laboratory studies of the material.

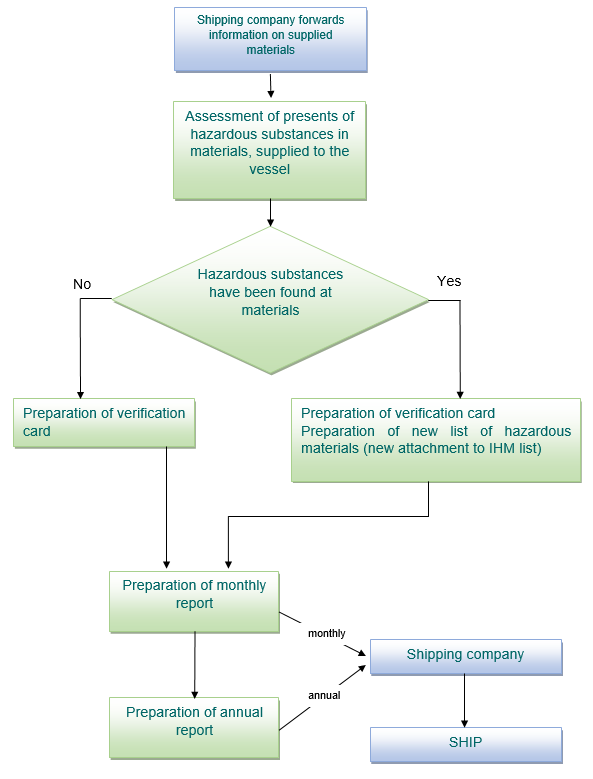

The material evaluation process is carried out in the following order.

1. Actions of the shipping company:

1.1. Ship in service:

A shipping company, supplying any kind of materials, equipment, mechanisms, devices, etc. on board a vessel, must inform the IHM company at least in the following:

The information can be provided in a format convenient for the shipping company.

Information should be sent to e-mail: safety@ims-group.org

It is highly recommended to provide accompanying certificates for materials (if any) together with the a/m data.

To exclude the ingress of extremely hazardous substances, such as asbestos, on board the vessel, it is recommended to provide information before, or in conjunction with the supplied material.

1.2. Ship during repair.

At a ship repair facility, in cases of replacement of ship structures and / or equipment, hazardous materials controlled under the IHM convention may appear in the ship.

The following information must be sent to the IHM company before the vessel is put into repair, and throughout the repair work:

Particular attention should be paid to reporting documents on:

2. Actions of the IHM company:

After receiving information about the supplied material, the IHM company, carries out an assessment for the presence of hazardous substances in the material in accordance with the one of the following:

Based on the results of checking each material supplied on board the vessel, the IHM company prepared the card which proof for the presence or absence of hazardous substances in the material. This card prepared in English language and includes the following information:

All cards, in electronic form, are available to the shipping company through the personal account of the EMI system on an permanent basis.

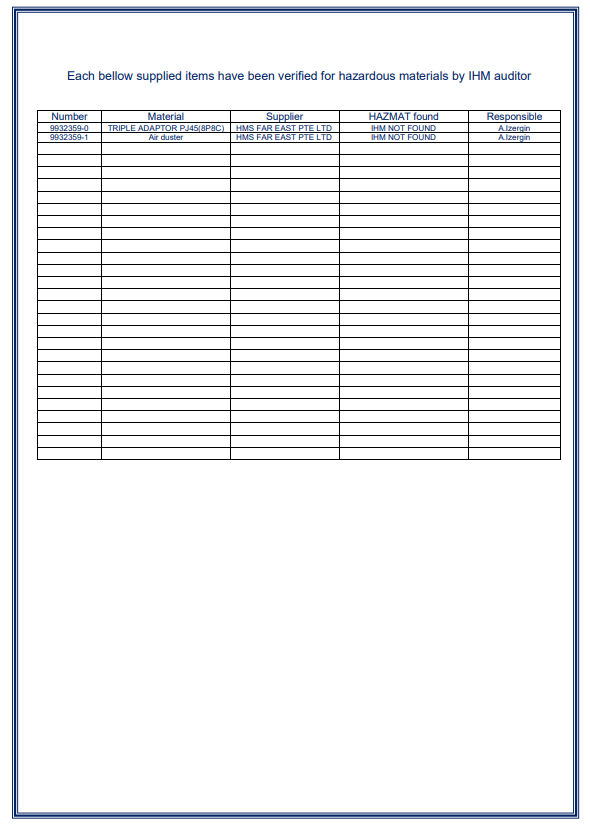

At the end of each month, a Monthly Report (Form IHM-2, see Appendix 2) is submitted to the shipping company electronically, where lists all the materials checked for the month. Verification cards should be attached to monthly report.

It is recommended that the monthly report be available on board in “hard” form. Inspection cards can be kept in electronic form and presented on demand to supervising organizations.

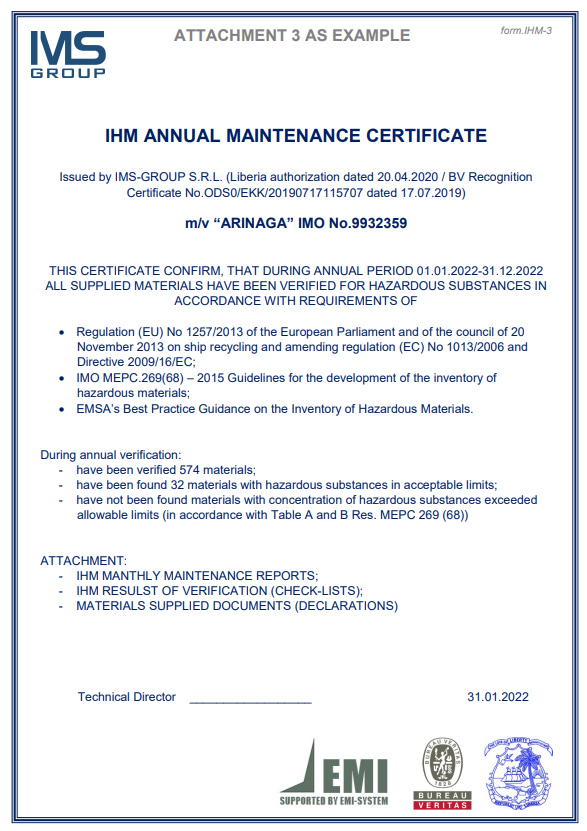

At the end of the reporting period (12 months), the company is provided with an Annual Report (Form IHM-3, see Appendix 3), which confirms the results of all inspections during the year.

If hazardous substances are found in the supplied material - changes are made to the existing list of hazardous materials - Table 1, Table 2 and Table 3. The changes are carried out by adding an Attachment with current tables to the existing IHM list.

New Supplements are sent together with the Monthly Report and must be appended to the existing IHM list.

The EMI system constantly maintains an up-to-date list of hazardous materials (Table 1, Table 2, Table 3).

Registration and reporting documents

Form IHM-1 - See Appendix 1.

This form confirms that the IHM company, on behalf of the shipowner company, has undertaken service for record and control all materials supplied on board the vessel for the presence of hazardous substances.

This form must be available on board to any inspectors and supervisors. The form includes the contact details of the IHM company and information on qualifications and accreditation.

The results of the assessment of hazardous materials supplied on board the vessel are provided to the shipping company in the following form:

1. Monthly Report (Form IHM-2) - see Appendix 2. Delivered to the shipping company on a monthly basis and reflects information on verified materials during this period.

2. Annual Report (Form IHM-3) - see Appendix 3. It is delivered to the shipping company annually and reflects information on verified materials for the reporting annual period, as well as all attached documents (including verification cards declarations for the supplied materials).

Online access to results.

Permanent online access to the results of accounting and control of materials supplied on board the vessel is carried out through the personal account of the EMI system.

In electronic form, the shipping company provides information on: